Simulation of Tires Using Ansys

Tires are an essential component for all types of vehicles. It is important to understand how tires perform under different speeds, loads and operating conditions. Ansys offers a depth of capabilities to perform comprehensive tire simulations including mounting, inflation, loading, footprint, and steady state rolling.

The team at Ozen Engineering offers customers deep technical experience in tire simulation to achieve accurate modeling results quickly.

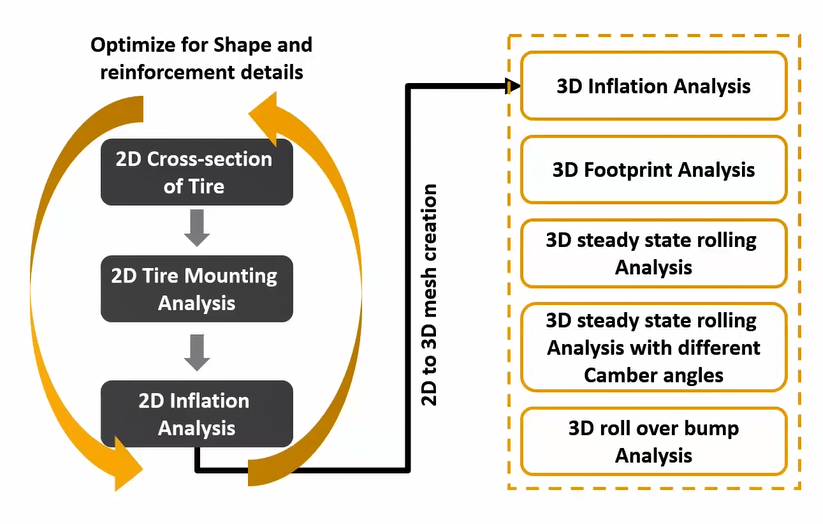

Typical Tire Simulation Steps

Users can consider the full history of tires in-operation to gain in-depth understanding of performance.

These steps are:

In Mounting, frictional contact between the tire and rim is modeled.

|

In Inflation, the effects of air pressure in the tire is modeled.

|

|

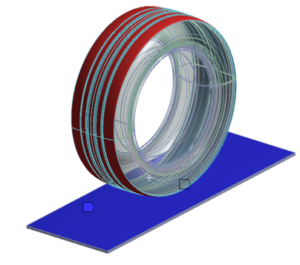

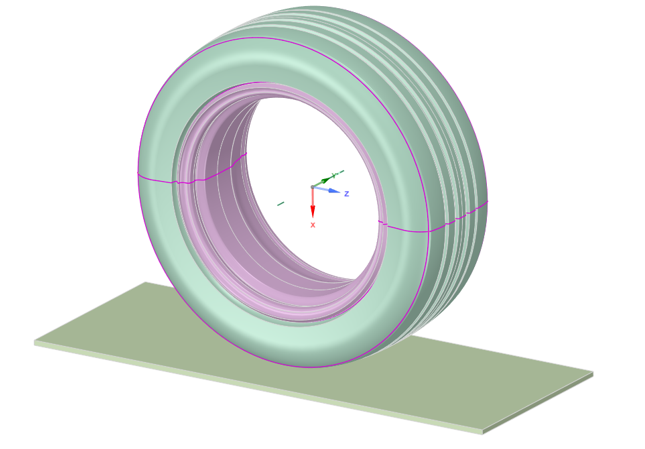

In Ground Contact, the effect of vehicle weight and road contact that result in tire deformation is modeled.

|

|

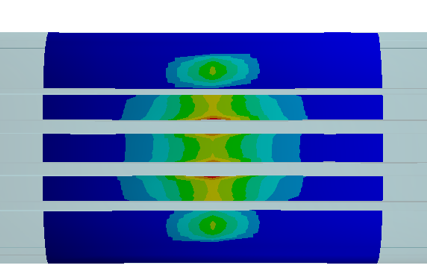

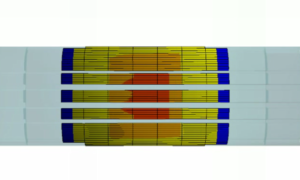

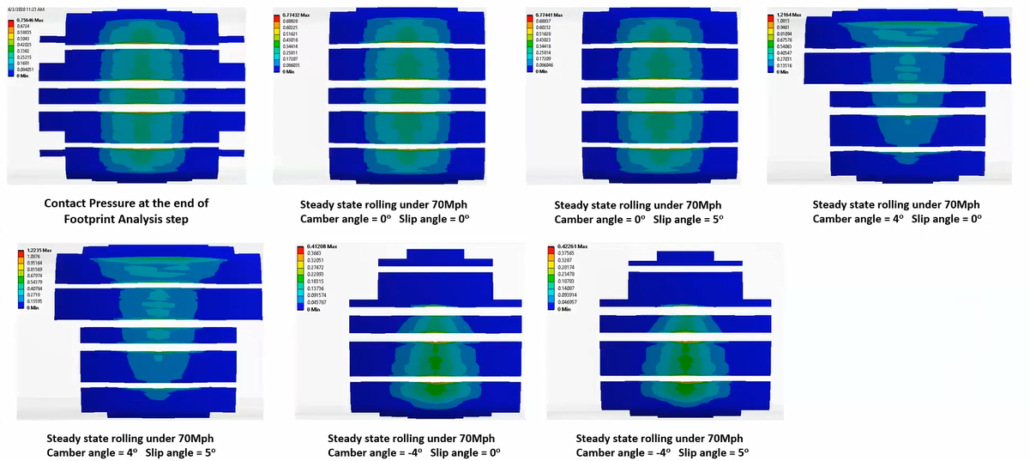

In footprint analysis, the contact pressure and contact status results are obtained.

|

In steady state rolling, tire performance is calculated for a moving vehicle operating under different typical conditions.

Tire Simulation Using Ansys

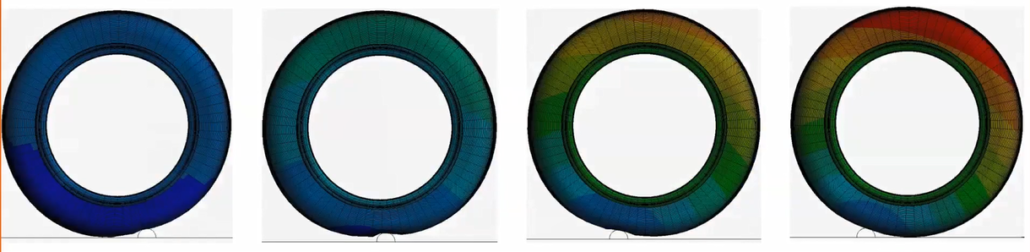

Engineers can perform detailed tire analysis in a straightforward way. The analysis could be based on static structure analysis or transient analysis.

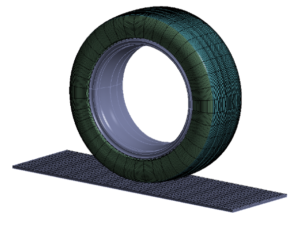

Transient analysis is used to study different aspects of the tire such as crossing over a bump, or rolling over time…etc.

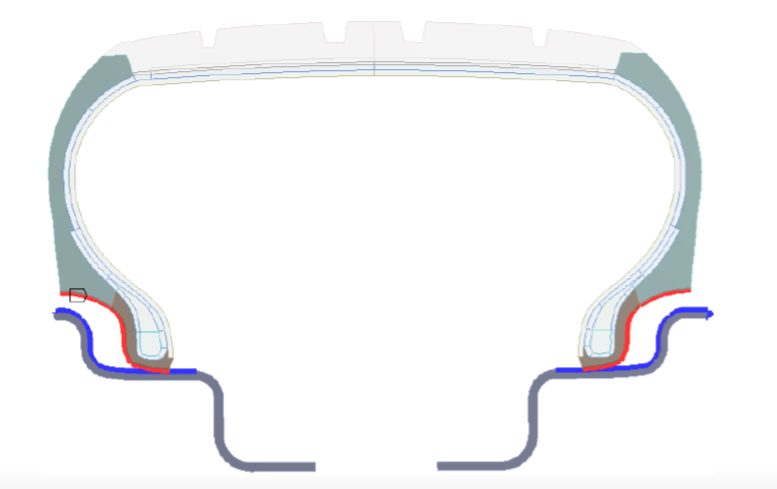

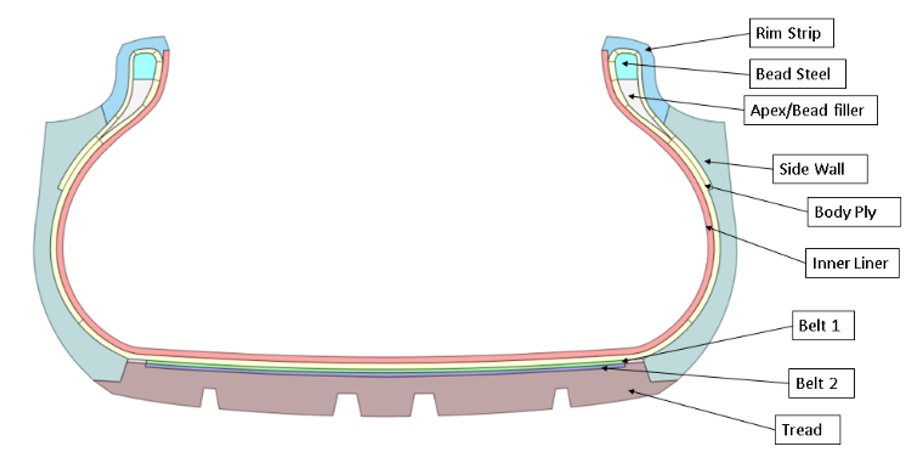

A detailed 2D cross section is all that is needed to start a detailed 3D tire simulation. All parts of the tire can be included, including reinforcement materials in detail and a suitable material will be assigned to each part. Using the ANSYS material library, you can use/define different materials including linear and nonlinear properties.

|

|

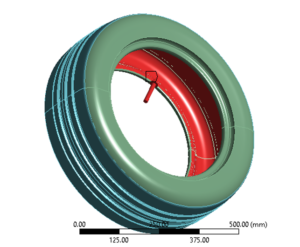

- Tire simulation is performed in the intuitive Ansys Workbench user interface to setup the mesh, contact conditions, and analysis settings.

- Boundary conditions include inflation pressure, weight load, friction coefficient, speed, and more.

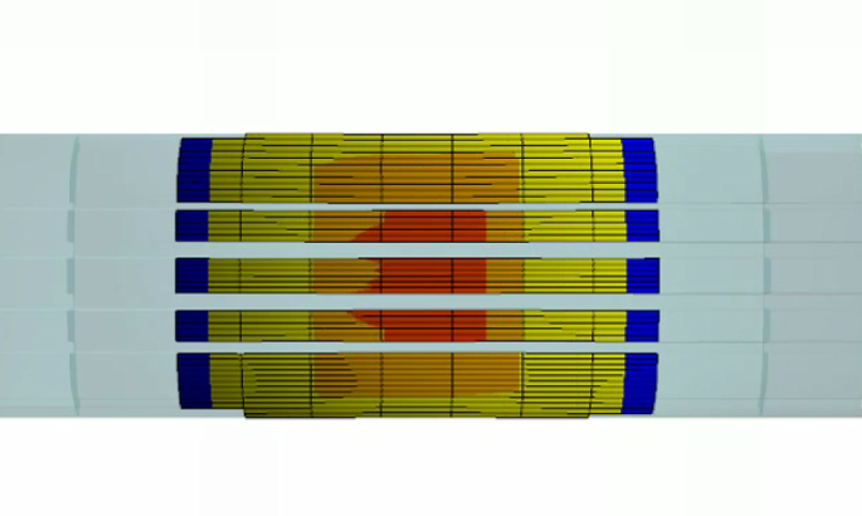

- ANSYS offers tools to include compute-efficient steel reinforcement for belts and plys.

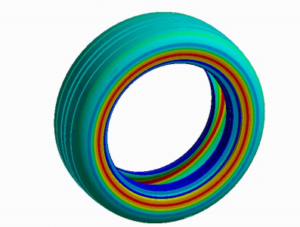

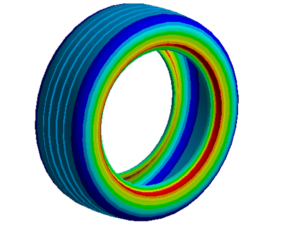

ANSYS tire simulation provides various results of interest, including: tire deformation, footprint contact pressure, stress and strain at every step of the simulation.

|

|

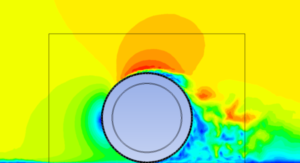

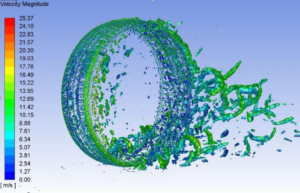

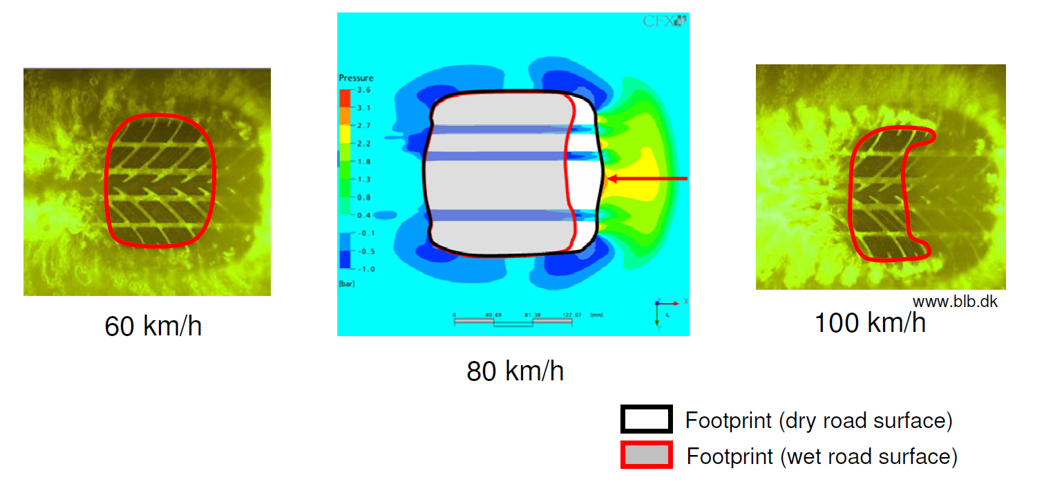

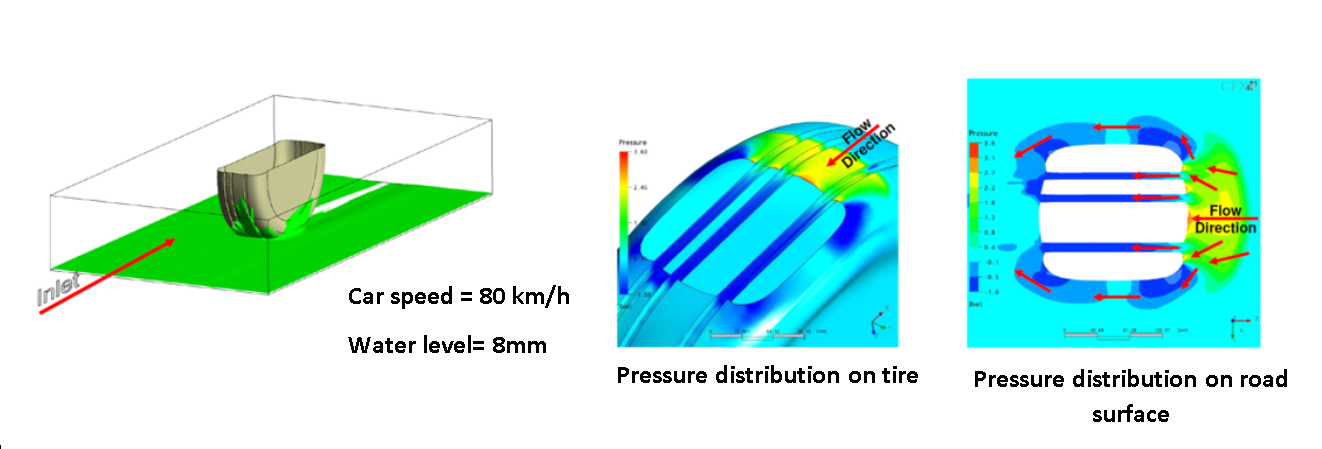

Tire Simulation Using CFD and Rigid-Flexible Dynamics

With Ansys, tire design teams can predict aeroacoustic noise and hydroplaning risk

|

|

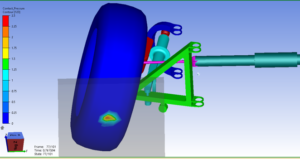

Tire design teams can evaluate the impact of components and tires on vehicle dynamics using Ansys/Motion.

Contact us to learn more or to schedule a demonstration.

- The Path of Least Resistance

- Tire Aero Acoustics

- Significance-of-Simulation-in-the-Journey-of-Tire-from-Rubber-to-Road

- Accurately Predict Automotive Aeroacoustic Noise for a Quieter Ride

![Ansys-elite-channel-partner-horizontal-reversed[1]](https://www.ozeninc.com/uploads/2022/06/Ansys-elite-channel-partner-horizontal-reversed1.png)