Additive Capabilities

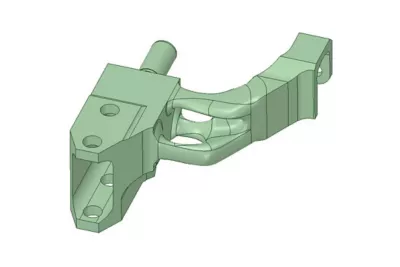

Design for AM (DfAM)

- CAD Modeling

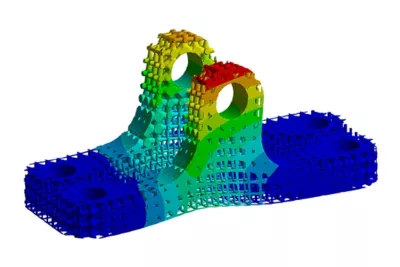

- Topology Optimization

- Lattice and Light weighting

Design for AM (DfAM)

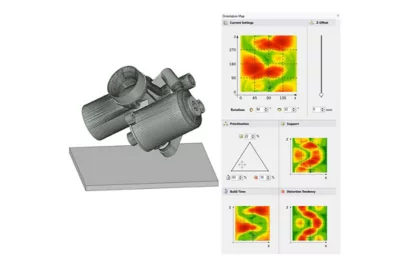

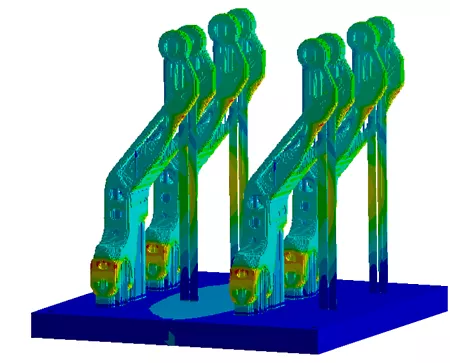

Build Setup

- STL file repair and geometry manipulation

- Part nesting and support generation

- Orientation guidance and wizards

Build Setup

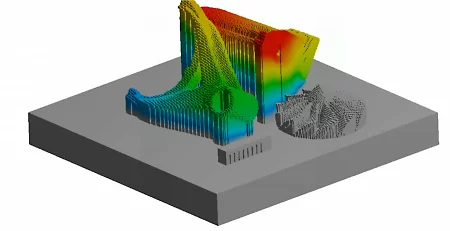

Process Simulation

- Metal AM process simulations

- Distortion compensation

- Build failure prediction

Process Simulation

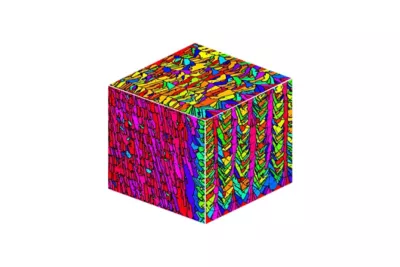

Material Analysis

- Curated material property databases

- Grain morphology predictions

- Melt pool and porosity prediction

Material Analysis

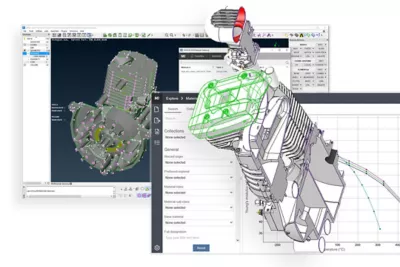

Data Acquisition and Management

- Traceability and full control of AM data

- Consolidate, control and share AM data across organization

Data Acquisition and Management

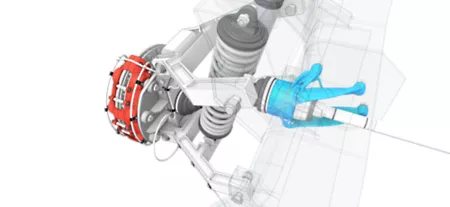

Part Qualification

- Design validation

- Structural and thermal analysis

- Document control and certification

![Ansys-elite-channel-partner-horizontal-reversed[1]](https://www.ozeninc.com/uploads/2022/06/Ansys-elite-channel-partner-horizontal-reversed1.png)