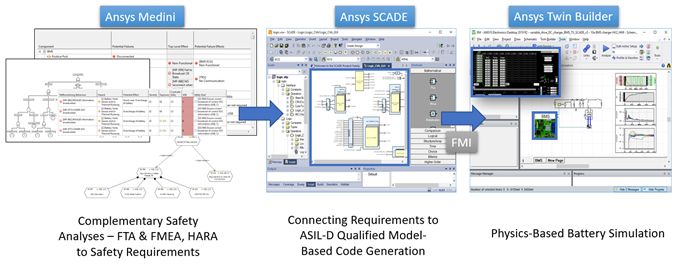

Battery Management System (BMS) is crucial to battery pack safety and performance. BMS is batterie’s control center and keeps cells within specified operating range and shuts off battery when safety issues are detected. Software & hardware work in tandem to monitor battery performance and usage. BMS impacts weight, mechanical and thermal subsystems and requires compliance to Functional Safety Standards such as ISO 26262 (ASIL C, D). Ansys solution is to use Medini, SCADE and Twin Builder in tandem to develop the BMS in a very efficient way as the following

- Using Ansys Medini for Safety analyses i.e. FTA, FEMA and HARA

- Ansys SCADE to connect safety requirements to generate a compliant code (Model Based)

- Using Twin Builder to do Physics-Based Battery Simulation

Fig. 1) Steps of developing and testing BMS using Medini, SCADE and finally Twin Builder

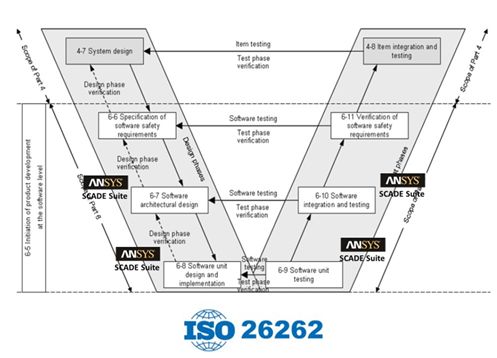

Fig. 2) A cost-effective solution for the development and verification of BMS

The benefits of using Ansys method can be listed as below:

- ANSYS Medini supports all Functional Safety Activities for ISO 26262

- ANSYS SCADE flow supports all software development activities for ISO 26262, ASPICE, AUTOSAR

- The gains of the approach are 40% to 50% of cost reduction demonstrated on user cases

- 2x Increase in time to market: Early detection of flaws, automated production of readable, portable, high performance and high-quality codes, and improved long-term maintainability

Learn more about battery simulation solutions on our Battery Solutions webpage.